Product Introduction

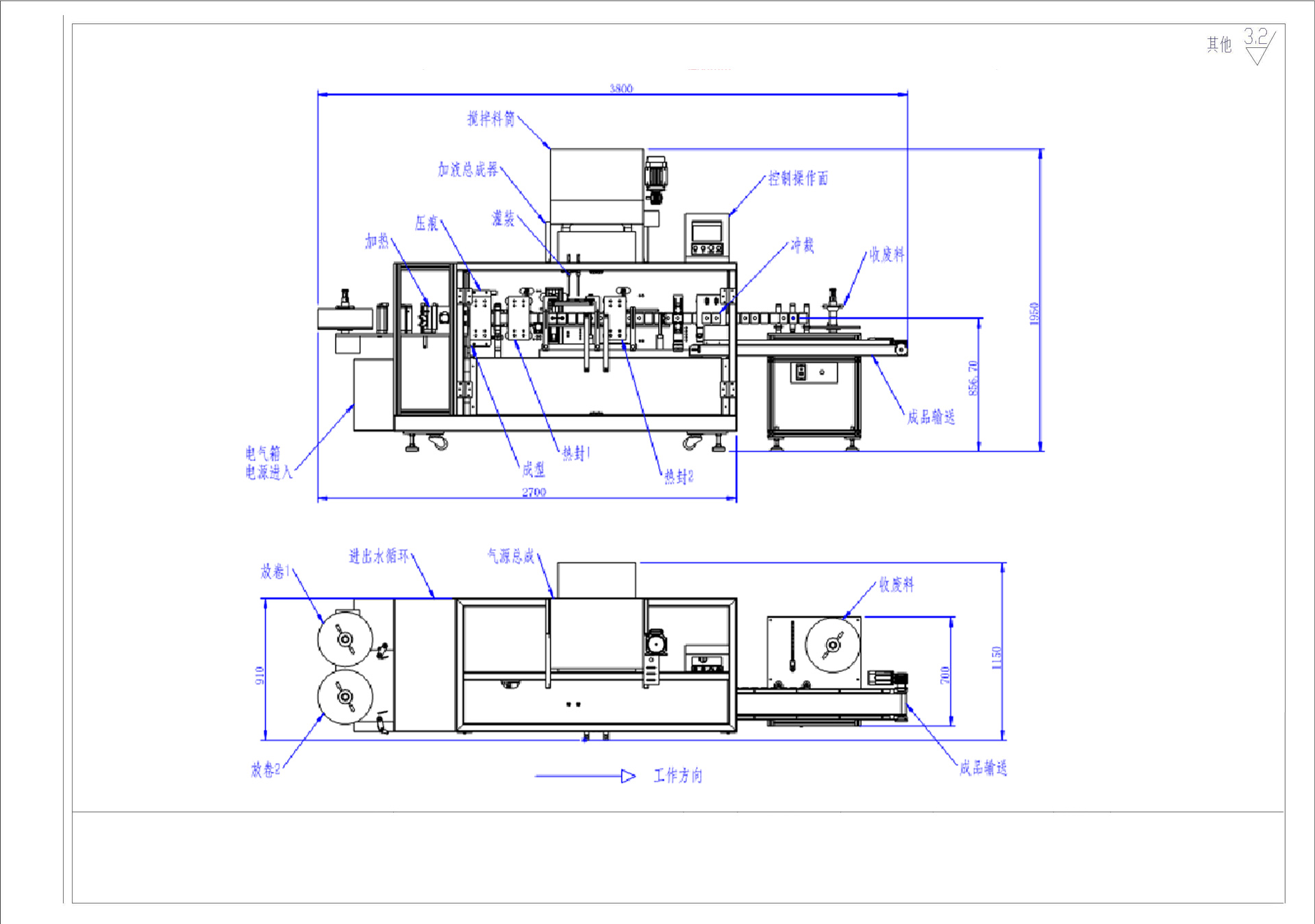

This machines main components include unwinding, heating, forming, creasing, filling, sealing, punching, scrap collection, and finished product output. The machines dispensing head is leak-proof, foam-proof, and spill-proof. Liquid-contact areas are constructed of stainless steel and meet GMP standards. The automated filling system ensures accurate metering with minimal error. This machine utilizes a human-machine interface, PLC control, and stepless frequency conversion for precise metering. It boasts high production speed, high efficiency, minimal footprint, compact structure, quick product and mold changeover, and low costs. It is suitable for high-volume production of a wide variety of products.